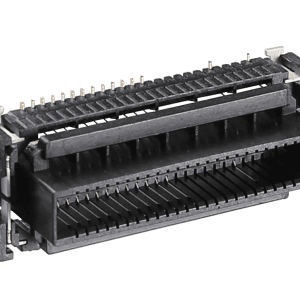

CNC Lathe Milling Machining Parts Aluminum Stainless Steel

Product Introduction

The processing technology of CNC Lathe Milling Machining Parts Aluminum Stainless Steel is CNC Micro machining.

We use the following craft such as broaching, drilling, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping.

The choice of raw material is Aluminum,Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel alloys, Others. We have supplied these CNC Lathe Milling Machining Parts Aluminum Stainless Steel to Boeing.

Product Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

Product Feature And Application

The Precision density of CNC Lathe Milling Machining Parts Aluminum Stainless Steel is extremely accuracy and critically quality control.

These machined parts are widely useful for Aerospace fields. In additional, the parts can be suitable to precision instruments, medical equipment, high-speed trains, automobiles, and other industries.

Product Details

The Tolerance of all dimension is between +/-0.005mm~+/-0.01mm.

These Aircraft Machining parts are controlled strictly in accordance with NADCAP – NDT certification standard. The large production volume is one of the most advantage.

FAQ

who are we?

Sunbright is a high-tech enterprise which integrates R&D, production and sales of high-end products and precision components. Products are widely used in communications, precision instruments, medical equipment, high-speed trains, auto, aviation and other industries.

how can we guarantee quality?

The workshop and production mass are strictly control in accordance with ISO 9001 and AS 9100D certification standard. The pre-production sample confirmed before mass production, final Inspection before shipment.

what can you buy from us?

CNC precision Machining parts including CNC turning and CNC milling, Custom CNC parts, CNC auto spare parts, Die casting parts, forging parts, Injection mold,mould etc.

what services can we provide?

We can provide CNC precision machining service, Sheet metal fabrication service, injection plastic mold service, some full products service of Beauty Care Tools and Top ornaments.

why should you buy from us not from other suppliers?

We are experienced in customization for over 20 years. With the concept of “pragmatism”, we provide customers with one-stop high-quality solutions from raw materials to process engineering and manufacturing. Products are widely used in communications, precision instruments, medical equipment, high-speed trains, auto, aviation and other industries.

Reviews

There are no reviews yet.