CNC Machined Stainless Steel Parts

CNC Machined Stainless Steel Parts Introduction

CNC Machined Stainless Steel Parts are precision-engineered parts that have been cut and shaped using computer numerical control (CNC) technology. Stainless steel is known for its durability and corrosion resistance, making it an ideal material for a wide range of industrial and engineering applications.

CNC Machined Stainless Steel Parts are used in industries such as aerospace, automotive, medical, and defense, where precision and reliability are critical. These parts can include components such as shafts, gears, bearings, valves, and fittings.

The CNC machining process involves the use of specialized software to design and program the parts, which are then cut and shaped using high-speed, automated tools and machines. This process ensures that the parts are made to the exact specifications and tolerances required for the application.

Overall, CNC Machined Stainless Steel Parts offer high strength, durability, and excellent resistance to corrosion, making them a reliable choice for a wide range of industrial and engineering applications.

You can rest assured to buy customized CNC Machined Stainless Steel Parts from us. Sunbright look forward to cooperating with you, if you want to know more, you can consult us now, we will reply to you in time!

CNC Machined Stainless Steel Parts Parameter (Specification)

The surface roughness is Ra 0.1-3.2.

CNC turning work range is φ0.5mm-φ150mm*300mm

CNC milling work range is 510mm*1020mm*500mm

CNC Machined Stainless Steel Parts Feature And Application

Features of CNC Machined Stainless Steel Parts:High precision – CNC machined stainless steel parts are manufactured using advanced computerized equipment that ensures high precision and accuracy in the finished product.High durability – Stainless steel is a highly durable material that is resistant to corrosion, rust, wear, and tear, making it an ideal material for industrial applications.Wide range of applications – CNC machined stainless steel parts are used in industries such as aerospace, automotive, medical, and defense, where precision and reliability are critical.Customizable – CNC machining allows for customization of parts according to specific customer requirements.Cost-effective – CNC machining is a cost-effective manufacturing method for producing high-quality stainless steel parts in large quantities.Applications of CNC Machined Stainless Steel Parts:Aerospace – CNC machined stainless steel parts are used in the aerospace industry for manufacturing aircraft parts such as landing gear, engine components, and control systems.Automotive – CNC machined stainless steel parts are used in the automotive industry for manufacturing components such as brake calipers, engine parts, and suspension components.Medical – CNC machined stainless steel parts are used in the medical industry for manufacturing surgical instruments, implants, and devices.Defense – CNC machined stainless steel parts are used in the defense industry for manufacturing components such as missile parts, gun components, and armored vehicles.Overall, CNC machined stainless steel parts offer high quality, precision, and durability, making them an ideal choice for critical applications in a wide range of industries.

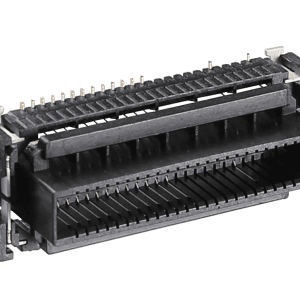

CNC Machined Stainless Steel Parts Details

The Tolerance of all dimension is between +/-0.005mm~+/-0.01mm.

These Aircraft Machining parts are controlled strictly in accordance with NADCAP – NDT certification standard. The large production volume is one of the most advantage.

Reviews

There are no reviews yet.