CNC Machining Medical Parts

As a professional high quality CNC Machining Medical Parts manufacture, you can rest assured to buy CNC Machining Medical Parts from our factory and we will offer you the best after-sale service and timely delivery. CNC machined items include various surgical instruments used in medical procedures, such as trocars (skin piercers), bone drills, and saws. When CNC machining, parts are typically milled using 3 to 5 axes or turned using a live tool CNC lathe. The most common types of machines used in the manufacturing of medical parts include CNC milling, lathe machining, drilling and computerized milling. Reliability and high quality are the top priorities in the processing of medical parts, so the medical device industry has put forward new requirements for professional precision tools. Difficult-to-machine materials, complex workpiece shapes, and frequent CNC small-batch production are critical for processing professional medical tools. Machine knives place high demands on them.

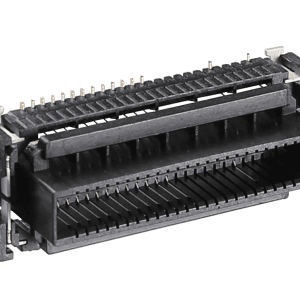

Product display

Product

- The requirements for cnc processing machine tools are relatively high

Advanced medical device processing equipment such as Swiss automatic lathes, multi-spindle machine tools and rotary tables are completely different from the usual machining centers and lathes. Their size is very small and their structure is very compact; to meet such requirements, the structure of the tool is also A special design is required, and the size of the tool is required to be small, while ensuring the rigidity of the tool.

- High requirements for cnc processing efficiency

For medical devices, the most important thing is the processing efficiency, that is, the processing tact, and it is required to be able to replace the blade in the shortest time.

- From the perspective of the workpiece itself, it is very different from other mechanical parts; medical devices implanted in the human body first require a very good finish, very high precision, and no deviation. From the design to the design of the insert coating, high machining requirements are met.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Sunbright Precision Hardware (Huizhou) Co., LTD. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.

Hot Tags: CNC Machining Medical Parts, Customized, Bulk, China, Low Price, Quality, Durable, Manufacturers, Suppliers, Price, Quotation

Reviews

There are no reviews yet.