Custom cnc milling machined parts

Our Custom cnc milling machined parts can produce custom prototypes and end-use production parts within 1 day. We use 3-axis milling ~ 5-axis indexing milling process to manufacture parts from more than 30 engineering grade magnesium alloy materials and aluminum alloys, stainless steel. We support turnkey completion to meet the visual and functional requirements of any design.

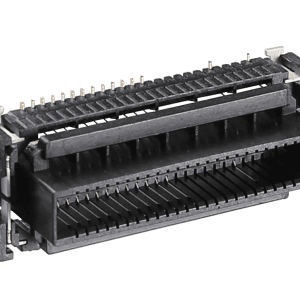

Product display

Product introduction

Compared with conventional machining, CNC milling has the characteristics of high machining accuracy, complex shape parts and wide machining range. According to the characteristics of CNC milling, we can roughly understand that the main types suitable for Custom cnc milling machined parts include the following types.

- Parts with complex structures such as curve contours or curved surfaces: the plane curve contour of the part, that is, the part has a complex curve with internal and external contours, and the processing surface is parallel or perpendicular to the horizontal plane. In three-dimensional space coordinates, the surface of a part is usually a point variation on the surface. It is usually designed by mathematical models. During the machining process, the milling cutter is always in point contact with the machined surface. The surface of the part is usually processed by three-coordinate CNC milling, because it needs to be programmed with the help of the CNC system.

- The structure of parts that are difficult to be processed by ordinary milling: For parts that are difficult to observe and control, such as size, scribing, detection, etc., because ordinary milling machines do not have CNC system to assist processing. Therefore, it is very suitable to choose CNC milling machine for these parts.

- Ordinary milling machines cannot achieve precision and accuracy: Due to the errors caused by human factors in ordinary milling, it is difficult to ensure the dimensional accuracy, shape accuracy and surface roughness of the parts. Therefore, if the precision of the parts is high, it is necessary to use a CNC milling machine for processing.

Product tolerance:+/-0.005mm

FAQ

Who we are?

Sunbright Precision Hardware (Huizhou) Co., LTD. is a metal parts manufacturer integrating development, design, production and sales. The company has advanced mold manufacturing and casting die-casting, forging, stamping, extrusion, turning and milling composite CNC machining, etc. Product assembly manufacturing capabilities. Products are widely used in communications, instruments, medical equipment, high-speed rail, trains, automobiles, aviation, automation equipment and other industries. According to the needs of customers, we provide one-stop services such as production, processing, polishing, oil injection, corrosion, electroplating and assembly of molds and hardware metal parts.

What services can we provide?

We can provide CNC turning, milling, turning and milling composite services, our metal mold processing services include stamping, die casting, forging, casting, powder metallurgy, and we also provide injection molding services, etc. We can provide you with more than 50 kinds of metals and plastics Materials, our more than two dozen surface treatments including electroplating, anodizing, painting, etc., can tailor a part solution for you according to your needs.

How do we guarantee quality?

Sunbright has successively passed ISO9001 certification, passed AS9100 aerospace quality management system standard certification, NDT-MT passed NADCAP certification, introduced ERP system in 2018, and implemented lean production in 2020. The company has a professional management team, strong technical force, advanced Production equipment, high-precision monitoring and measuring equipment, and perfect management system provide customers with high-quality products and services.

What equipment do we have?

Sunbright has more than 1,000 sets of CNC machining, EDM, punch, die-casting machines, forging equipment, casting equipment, and injection molding equipment, which can manufacture high-precision parts for you.Our testing equipment includes German ZEISS CMM three-coordinate instrument, German SPECTRO MAXx06 Spectrometer direct reading spectrometer, American Micro-Vu CMM optical three-coordinate instrument; American AD-2045 wet horizontal magnetic detector, American projector, Japan Mitutoyo profilometer, American pneumatic measuring instrument, Italian SYSTEM AFFRI hardness tester, German GARDNER gloss meter, Japan Keyence optical caliper and other precision testing equipment.

Hot Tags: Custom cnc milling machined parts, Customized, Bulk, China, Low Price, Quality, Durable, Manufacturers, Suppliers, Price, Quotation

Reviews

There are no reviews yet.